Powder Metallurgy

Powder metallurgy uses the sintering process for making various parts out of metal powder. The metal powder is compacted by placing in a closed metal cavity (the die) under pressure. This compacted material is placed in an oven and sintered* in a controlled atmosphere at high temperatures and the metal powders coalesce and form a solid. A second pressing operation, repressing, can be done prior to sintering to improve the compaction and the material properties.

*Sintered = is the process of compacting and forming a solid mass of material by heat and/or pressure without melting it to the point of liquefaction.

The properties of this solid are similar to cast or wrought materials of similar composition. Porosity can be adjusted by the amount of compaction. Usually single pressed products have high tensile strength but low elongation.

Powder metallurgy is useful in making parts that have irregular curves, or recesses that are hard to machine. It is suitable for high volume production with very little wastage of material. Secondary machining is virtually eliminated.

Typical parts that can be made with this process include cams, ratchets, sprockets, pawls, sintered bronze and iron bearings (impregnated with oil) and carbide tool tips.

EPOXY

Epoxy resins are reactive thermosetting polymer resins where the resin molecule contains one or more epoxide groups. Epoxies can be altered for the desired application and manufacturing process, for example an epoxy resin can be “toughened” with the addition of thermoplastic polymers.

Epoxy resins are cured with the addition of a curing agent, which is commonly called a hardener.

Advantages include:

- Low shrinkage,

- High adhesive strength,

- Good heat resistance.

- Excellent mechanical strength.

Therefore, epoxy resins find uses such as adhesives, as a binder in cements and mortars, casting compounds, sealants, varnishes and paints, as well as laminating resins for a variety of industrial applications. However, they can be relatively brittle.

Epoxy in composites

Epoxy resins make up the matrix structure used in some composites, it is brittle in nature and often reinforced using glass fibre, as in fibreglass or other reinforcement such as carbon fibre, in order to add strength to the composite. If there is damage to the fibre, for example pull out or damage to the fibre weave, the brittle resin structure that is left will be prone to cracking in that area.

Impact damage also often leads to delamination, often not visible on the surface, this is where the more brittle property of the resin fractures and pulls away from the fibre weave

Epoxy resin Powder

An epoxy resin powder is essentially a solvent free paint. Each epoxy powder particle contains base and curing agent, but they do not react together until they are activated with a heat source. Other ingredients in each powder particle are; pigment, accelerator, flow control agents and minor additives.

The component to be coated is preheated before the powder is applied by using a spray technique, usually via electrostatic methods to achieve more uniform thicknesses and to reduce powder wastage by overspraying.

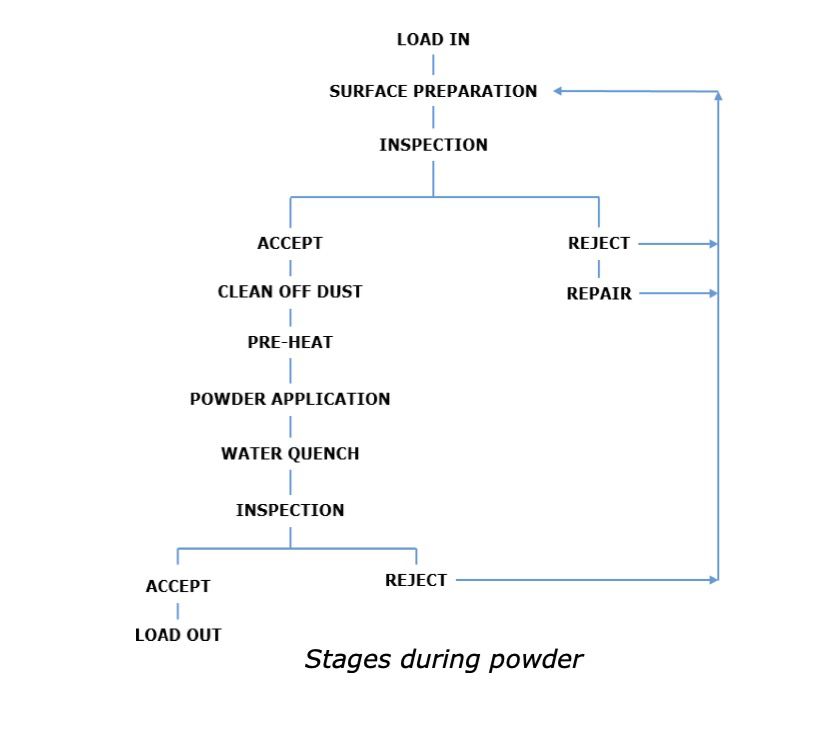

After application, the coating may sometimes be post-cured in a subsequent stoving operation. The following diagram shows a typical sequence of operations for coating pipes with epoxy powder in a pipe coating plant: